Lab-made meat may herald the next food revolution

Mail This Article

Wouldn't it be great if we can have the type of meat that we want to cook without slaughtering animals? It is no longer a fantasy. It may not be too long before we could dine on some delicious meat that looks, smells and tastes exactly like top quality organic grass-fed beef. But instead of deriving it from cattle, it will come from a bioreactor and will be exactly like the type of body part we want to experience.

In fact Sir Winston Churchill in 1932 fantasised: "We shall escape the absurdity of growing a whole chicken in order to eat the breast or wing by growing these parts separately under a suitable medium”. Today the concept of lab-grown meat also known as cultured meat, clean meat, synthetic meat, artificial meat or in vitro (outside the living body and in an artificial environment) meat has become a reality. Within 10-20 years of time most of us, regardless of which country we live in will be eating meat grown in a reactor. Lab-grown meat will be one of the disruptive technologies of this century just as the evolution of antibiotics, smart phones, self-driving cars, non-petroleum based cars, Uber, etc.

This technology is a form of cellular agriculture, where beef, chicken, wild animal meat and even fish can be grown in a clean environment in a bioreactor. Unlike in the conventional meat industry, the meat can be grown without the administration of antibiotics and hormones, but in a natural way. Grass-fed organic beef in US is five times more expensive than the regular beef. By syringing out a tiny piece of tissue from a healthy cow one can produce multi-ton quantities of beef of the same quality in a economical way. In other words two slaughtered cows can feed the whole meat-eating population of the entire world, reminding us the miracle of Jesus feeding 5,000 people with two fish.

By 2050, the world population will increase to 9 billion. Providing meat to 9 B people will be a big global environmental challenge. A research conducted by Hanna Tuomisto of Oxford University’s Wildlife Conservation Research Unit found that the environmental impacts of cultured meat could be substantially lower than those of meat produced in the conventional way. Cultured meat could potentially be produced with up to 96% lower greenhouse gas emissions, 45% less energy, 99% lower land use, and 96% lower water use than conventional meat.

Several international companies have invested into this technology and significant progress has already been made in this area. On August 5, 2013, Prof. Mark Post of Maastricht University in the Netherlands and the co-founder of Mosa Meat produced the world's first lab-grown burger at a news conference in London for taste test. Although it cost $325,000 to produce, within 2-3 years the estimated cost was reduced to $11. Very soon these types burgers might be available in selected restaurants with affordable prices.

US-based Memphis Meats, Israel-based SuperMeat, and Japan-based Shojinmeat are all heavily investing into this technology. Bill Gates (the main founder of Microsoft Corp), Richard Branson ( British billionaire), Tyson Foods, one of the biggest meat businesses in the world, and Cargill, the second-largest beef producer in the world, are also in the race.

How is it done?

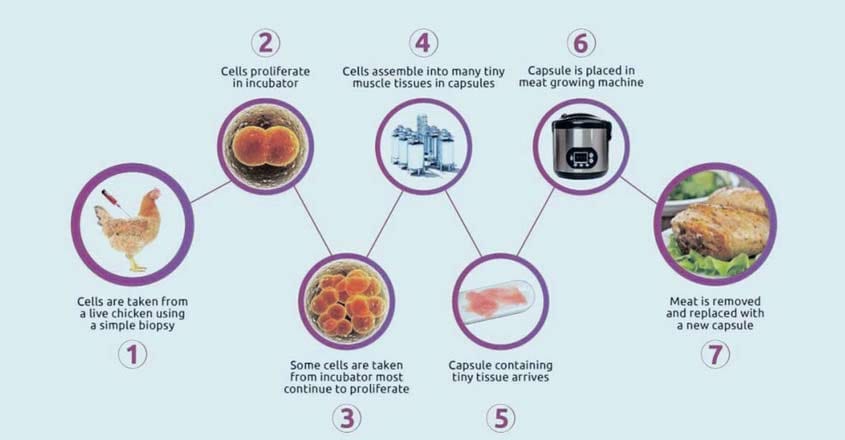

The technique adapted to grow meat in a lab is developed by tissue engineering. Using a biopsy technique a few cells are removed from the living animal. Different types of cells such as embryonic stem cells, adult stem cells, myosatellite cells, or myoblasts can have different characteristics. Cells such as myoblast cells are often used in this technology as they proliferate at an acceptable rate but also sufficiently differentiate from other types of cells. The cells are then treated with a protein that promotes tissue growth. These are then placed in a culture medium, in a bioreactor, which is able to supply the cells with the energetic requirements

needed to multiply. The interesting thing about this technology is that plant-based culture medium can be used to grow the meat. To culture three-dimensional meat, the cells are grown on a scaffold. The ideal scaffold is edible so the meat does not have to be removed, and periodically moves to stretch the developing muscle, thereby simulating the animal body during normal development.

From hamburger to steak?

During the taste test of the first lab-made hamburger, the food critics commented that it lacked the juiciness, although it had the good texture. This was due to the fact that the meat was grown to be 100% lean. Although the current technology allows to produce the hamburger meat with reasonable efficiency, research is ongoing to come up with different kinds of meat, for example rib eye or T- bone steak or beef for making curry or one to cater to customer’s different taste and perception (eg; colour, texture, appearance, etc).

Prof. Mark Post during the TED talk mentioned that he has been able to grow fat tissues from the fat stem cells. However, the big challenge was to incorporate the natural red colour, bone, fat and cartilage to look the meat exactly like the natural meat. Myoglobin is a protein that stores oxygen in muscle cells. It is very similar to its cousin, haemoglobin, that stores oxygen in red blood cells and is responsible for giving red colour to the meat. Prof. Post had to add beat juice in the 2003 hamburger to mimic the colour. Since then his group has been able to increase myoglobin content by five fold by starving the stem cells.

In addition circulation of oxygen and nutrients such as poly unsaturated fats in the cells needs to be further improved by channel and flow system. With the help of tissue engineering, material science and 3D bioprinting, Prof. Post thinks that we are not far away to get used to cook and perhaps grow meat in our kitchen using the stem cells that we receive from internet companies such as Amazon. At home just as the refrigerator an incubator which maintains 37 deg C temperature can be used to grow the meat in theory. However, we have to plan 8 weeks in advance what we want to have for dinner if we want to grow our own meat in a kitchen, he joked.

References:

Churchil’s 1932 article for Mechanics Illustrated was titled “Fifty Years Hence.”

World's first lab-grown burger is eaten in London

(Dr Thomas J Colacot is the director of Global Technology Innovation, Millipore Sigma (Business of Merck KGaA).)